This "Guide for Irradiation Experiments in TREAT" (hereinafter referred to as "Guide") provides prospective experimenters (hereinafter referred to as "experimenter") with initial guidance and requirements for performing experiment irradiations in the Transient Reactor Test (TREAT) Facility. The Guide describes the technical requirements for materials inserted into the TREAT reactor (hereinafter referred to as "Reactor") and the conditions that apply with the associated process for conducting an irradiation experiment.

This Guide is intended to provide experimenters the basics necessary for concept development and initial experiment planning, but is not intended to address every aspect and scenario of potential experiments. An experienced team at INL and TREAT will work with experimenters to finalize experiment development and ensure full compliance with all requirements. Experimenters are encouraged to educate themselves on the design and operation of the Reactor through a review of reports listed in the reference section of this Guide.

TREAT is located at the Materials and Fuels Complex (MFC) of Idaho National Laboratory (INL) and is a versatile test facility that houses the Transient Test Reactor. The Reactor uses high-power, short-duration nuclear radiation exposure to irradiate samples, primarily to simulate nuclear reactor accident conditions. Transient testing is a critical component in advancing nuclear energy reserach and development for a new generation of reactors and nuclear fuels, enabling future deployment of advanced nuclear power systems. Virtually every nuclear reactor technology in use today has benefited from historical experiment programs conducted at TREAT.

The Reactor first achieved criticality in 1959 and was operated successfully until it was placed in safe standby mode in 1994. The Reactor remained fueled and in standby while additional TREAT facilities were used for other INL mission activities until the Department of Energy Office of Nuclear Energy (DOE-NE) identified a broad need to reestablish transient testing capability in the United States. In 2014, resumption of operations at TREAT were approved. The TREAT Restart team completed efforts to resume operations in August 2017 and brought the Reactor to critical in November 2017.

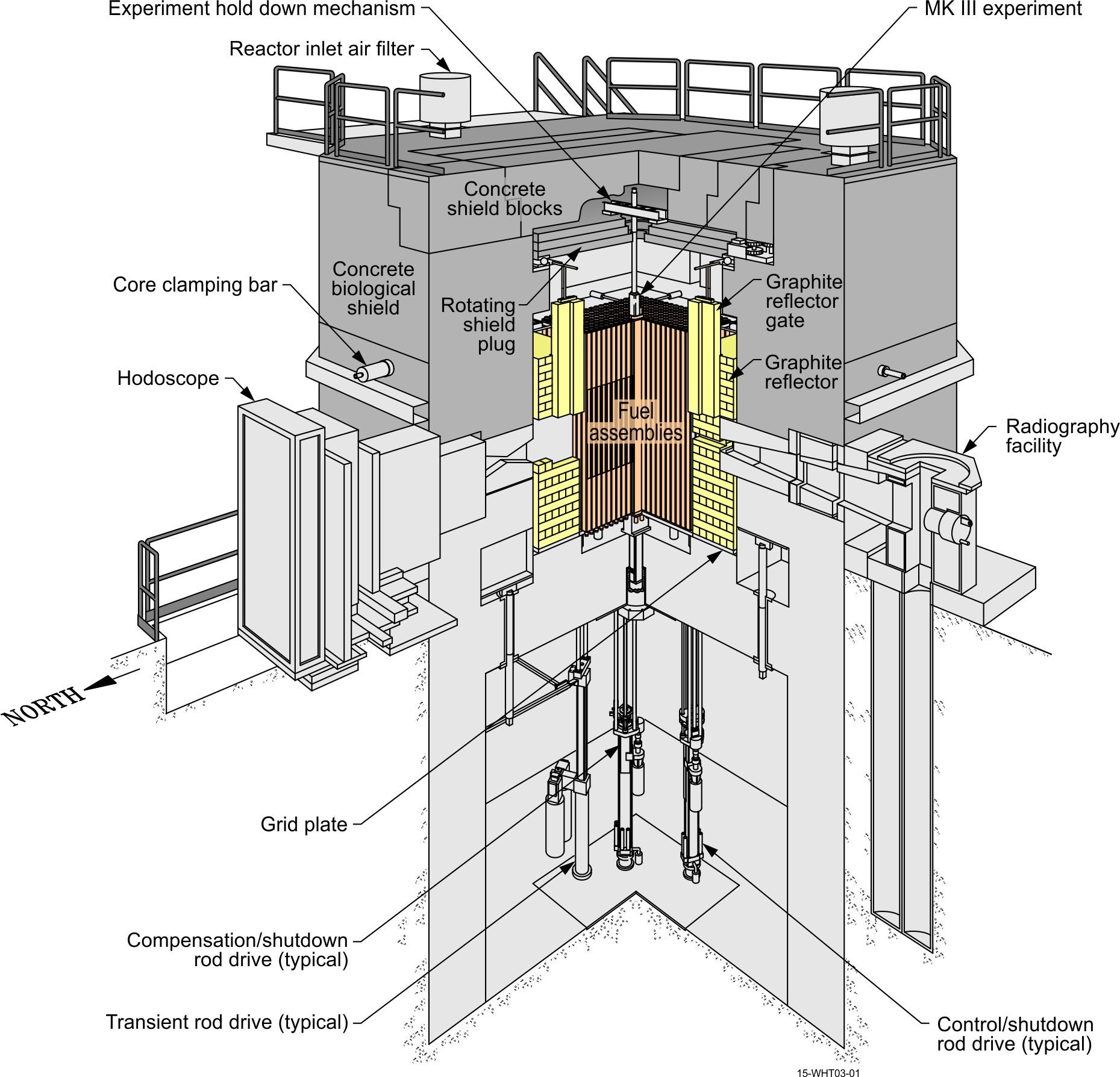

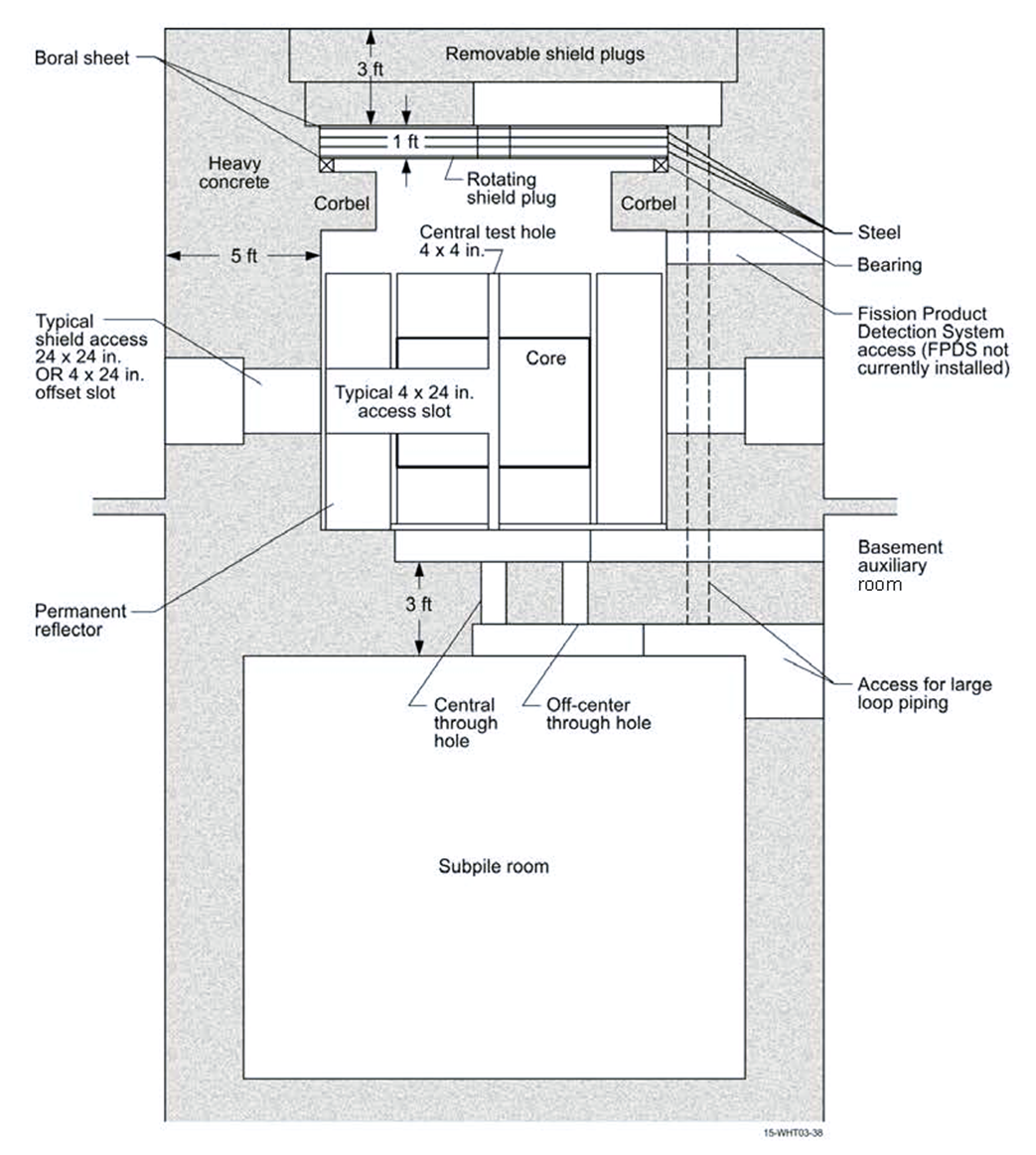

The Reactor is air-cooled and contains fuel assemblies comprised of uranium dispersed in graphite blocks and encapsulated in zirconium alloy. The Reactor is best suited to self‑contained experiment devices, which can be transported in shielded casks and lowered directly into the core with plug in connections for power, instrumentation, and other necessary leads. The ability to accommodate test devices by simple "lower in" installation through the rotating shield plug in the top of the Reactor enables testing of various types of specimens in different test vehicles with little downtime between experiments. Highly radioactive experiments can be assembled nearby in hot cell facilities, transported in shielded casks, and returned to the hot cell for disassembly.

Experiment devices typically displace one or two adjacent fuel assemblies in the Reactor core, creating a test cavity of either 4 × 4 in. or 4 × 8 in. in the center of the core with 47-5/8-in. of active core heigh. However, larger tests can be accommodated with some reduction in the energy deposited in the test specimen.

Attached to the Reactor is the fast neutron hodoscope, a unique instrument that detects neutrons and records real-time evaluation of the fuel behavior within a test sample. In addition to transient data, the hodoscope is also capable of generating a fast-neutron radiograph of the test section both before and after the transient test. Post-irradiation examination (PIE) performed on the experiment loops provides physical evidence of the transient end results while the hodoscope provides information on how it got there. The hodoscope is the primary diagnostic instrument used at TREAT and the measurements taken by the hodoscope are used to validate computer codes used in full-scale reactors to analyze accident conditions.

Besides transient experiments, the Reactor is capable of neutron radiography of experimental capsules and elements that have been performed at TREAT or in other reactors. This capability supports the study of fuel meltdowns, metal-water reactions, and thermal interaction between overheated fuel and coolant, and the transient behavior of reactor fuel for a variety of systems.

INL has additional ancillary capabilities across the laboratory to support irradiation experiment development and PIE that may be of interest to the experimenter and available to support TREAT experiments. TREAT will provide additional information on these capabilities upon request.

With the ability to directly couple the response of material systems to complex reactor environments under a variety of reactor operational conditions and off-normal transient events, TREAT provides a range of unmatched capabilities supporting fundamental science and the development of advanced nuclear fuels and material technology. Basic data collected from experiments can predict the safety margin of fuel designs, the severity of potential accidents, and serve as a proving ground for fuel concepts designed to preclude the consequent hazards.

This one-of-a-kind reactor is sought by a variety of experimenters. Battelle Energy Alliance (BEA) is responsible to DOE for the management and safe operation of the Reactor and TREAT facilities in a manner that minimizes risk and maximizes programmatic accomplishments. This Guide has been developed to ensure this responsibility is realized to the greatest extent possible.

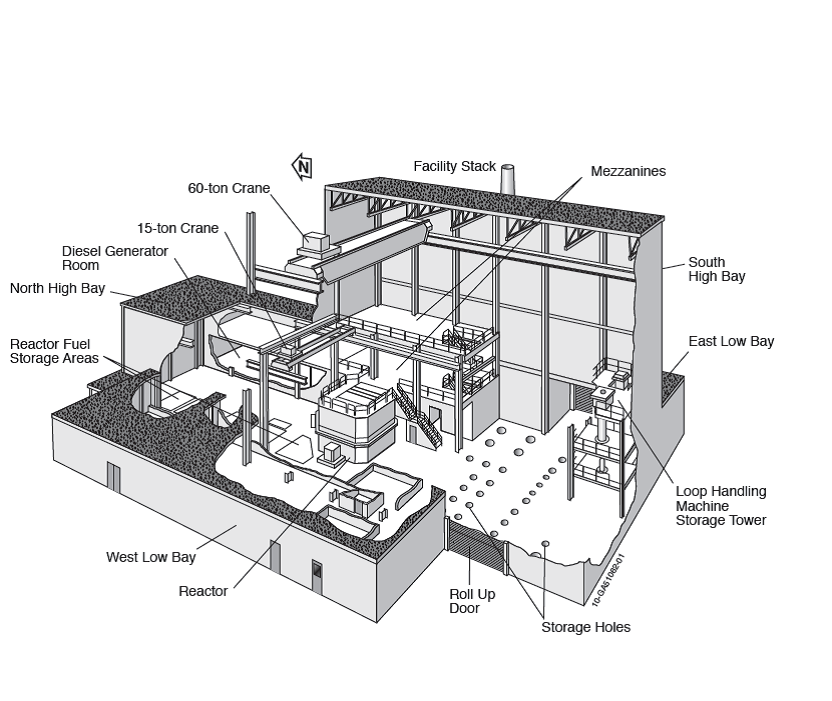

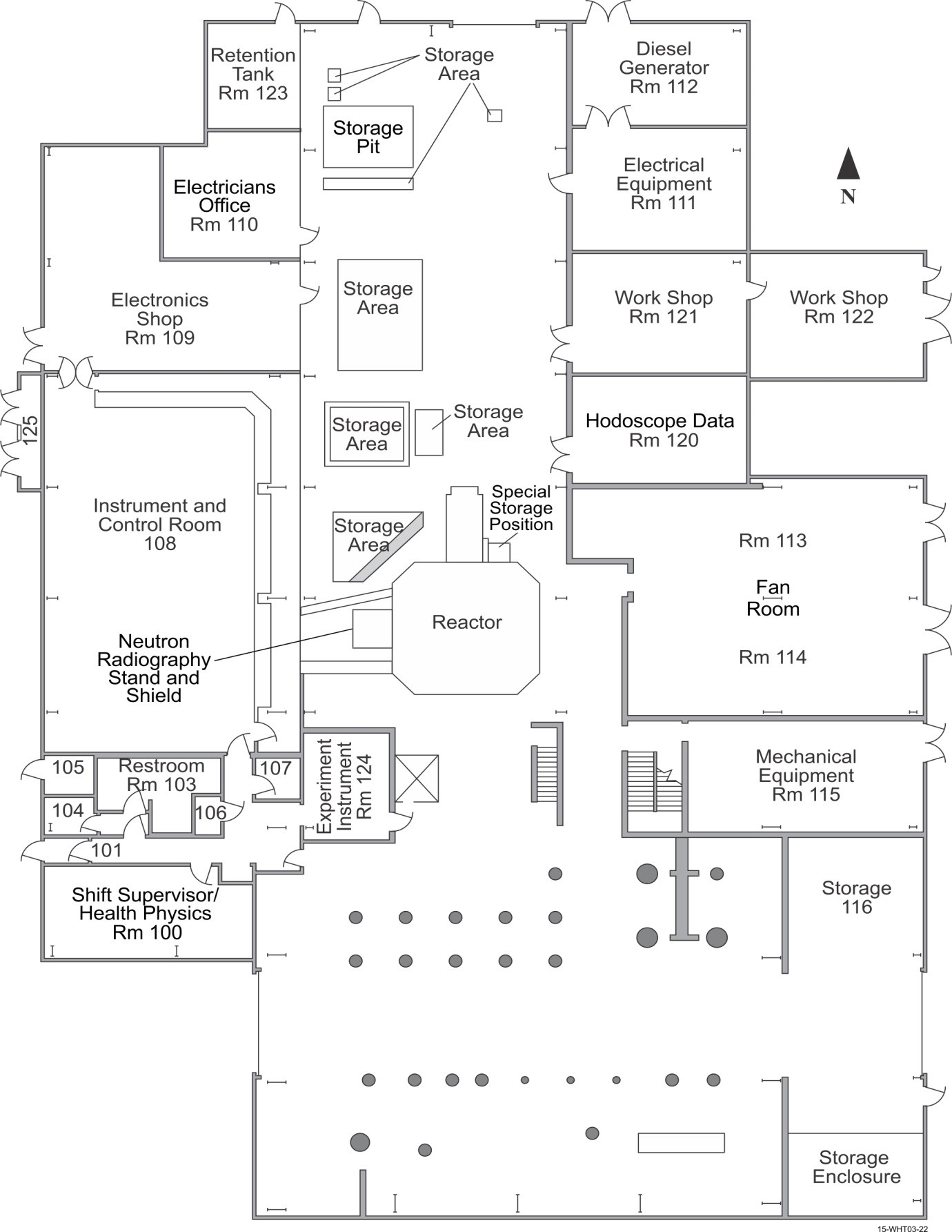

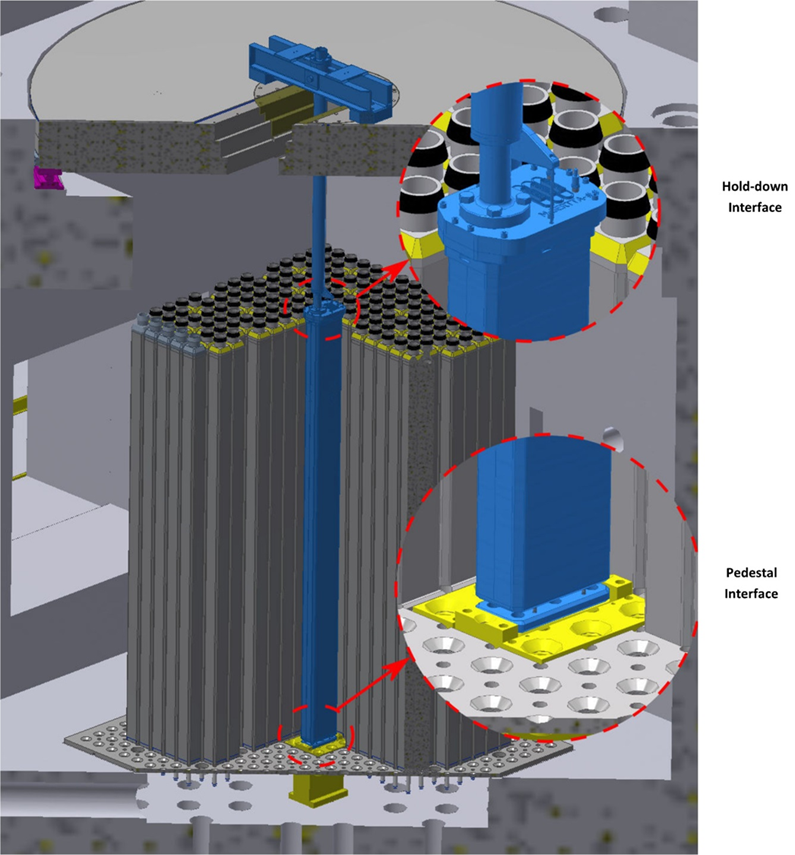

A TREAT cutaway view (Figure 1) and detailed floor plan (Figure 2) show the various rooms that support the Reactor. A schematic of the Reactor (Figure 3) the core of the Reactor (Figure 4) and cutaway view of the reactor structure (Figure 5) are supplied for reference.

Figure 1. TREAT cutaway view.

Figure 2. TREAT floor plan

Figure 3. TREAT Reactor schematic.

Figure 4. TREAT core schematic.

Figure 5. TREAT reactor concrete structure.